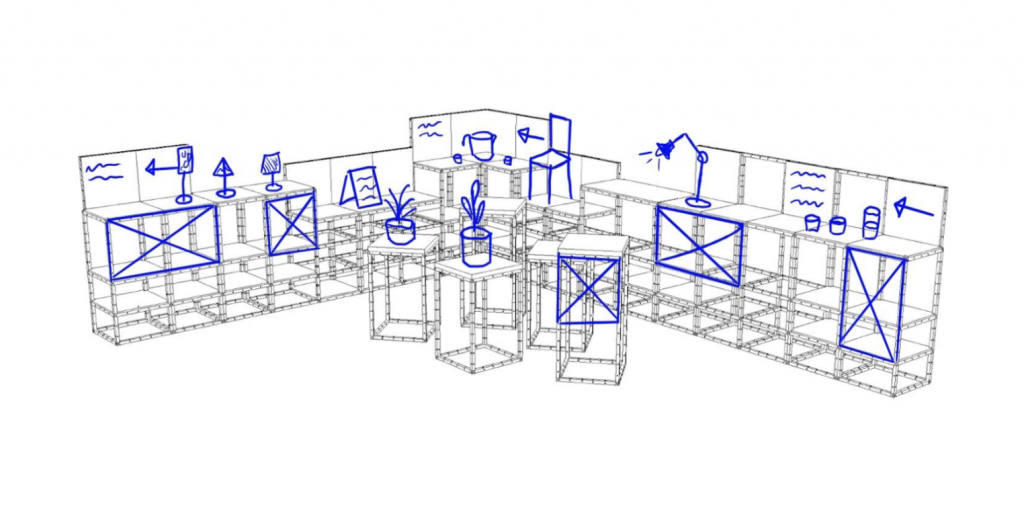

As part of the CIRCuIT (Circular construction in regenerative cities) project we challenged students from the University of Brighton to “use design-for-disassembly to build exhibition furniture that lasts over five years”.

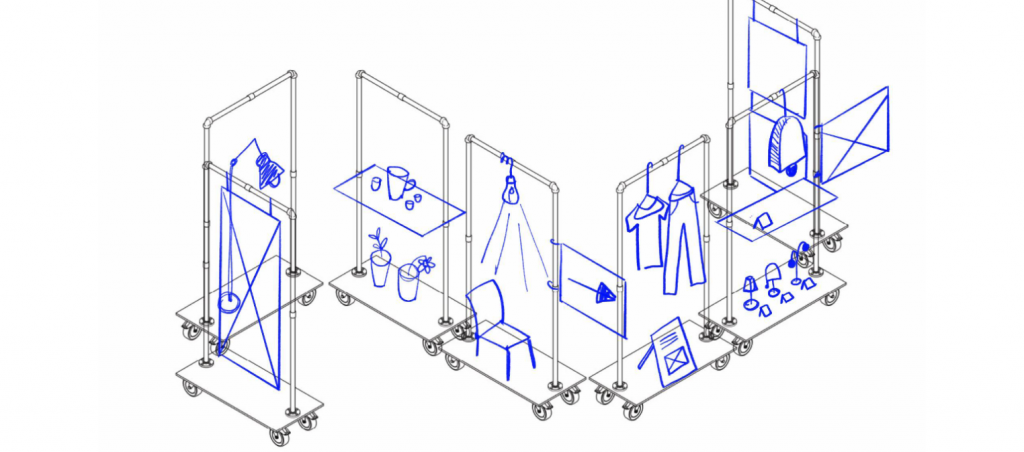

The focus of the hackathons have been around the creation of modular exhibition display furniture, able to be disassembled and reassembled multiple times.

STUDIO MAKE

The first hackathon was with a team of Brighton Product Design final year students calling themselves STUDIO MAKE

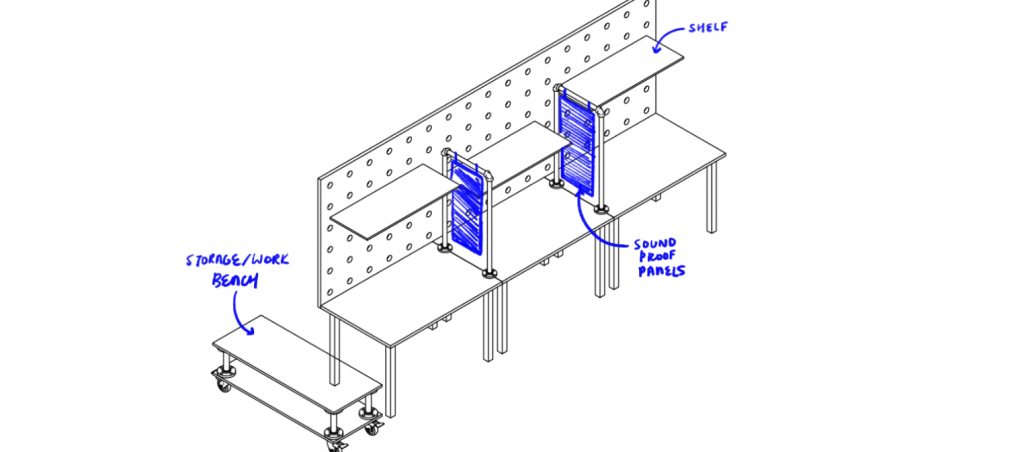

Initial meetings with students explored design for disassembly, flexible construction techniques, and how these might work in combination with fablab/makerspace principles and methodologies.

The students then ran a co-design sprint to generate ideas, resulting in 3 proposed ideas that had exhibition setting and post exhibition uses.

BRANCH

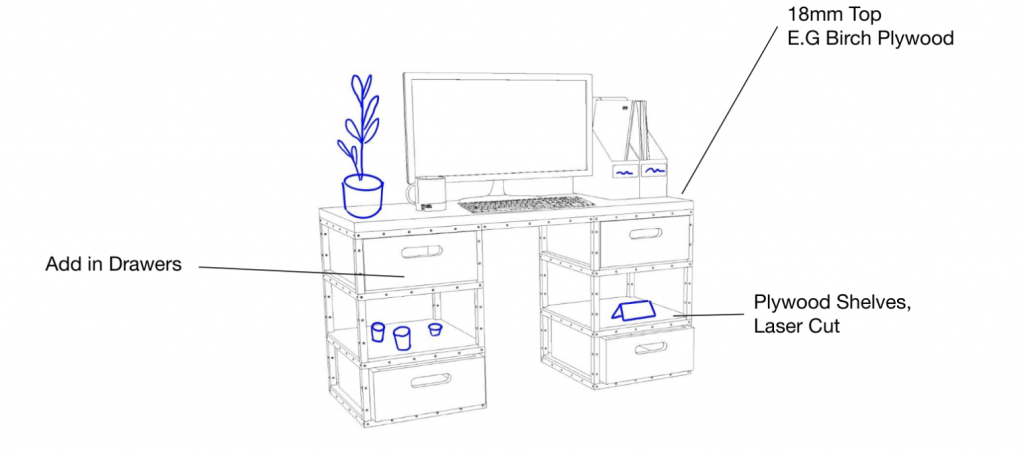

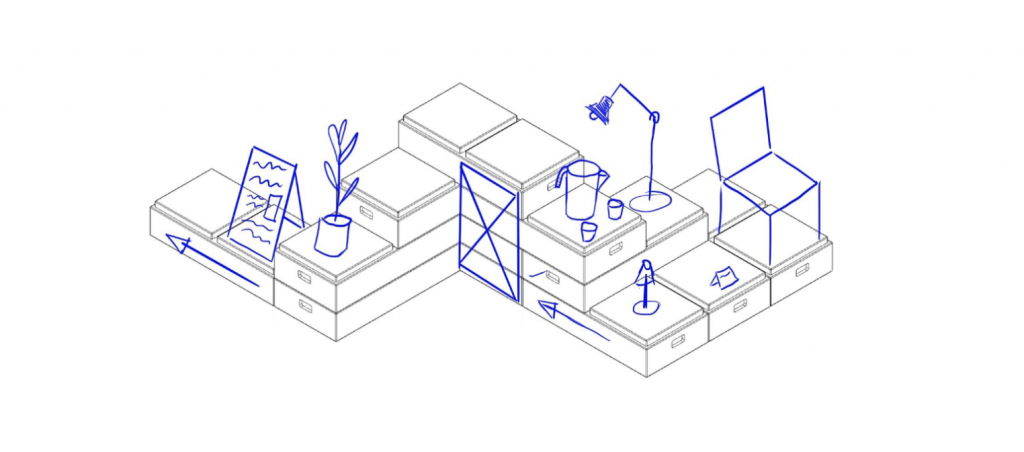

Building on the research and proposed brief carried out by the first set of students, we then worked with student, James Cann (See portfolio here) to develop a 3D printed corner bracket that could be used as a hub for a modular unit for the University of Brighton final degree exhibition as well as an upcoming London Design Festival exhibition.

James’ project, Branch uses a 3D printing technique where thick layers are extruded in a continuous ‘spiralized’ path. This technique, significantly decreases print time through depositing a large amount of PLA (plastic) in a single layer and removing any movements where the 3D printer is not extruding material (essentially extruding a continuous line of filament).

To optimize the design for strength and flexibility we organised a hackathon at Batch.Works where we prototyped the construction of the exhibition and directly work on required improvements to the 3D printed fixings.

With a finalised 3D printed corner fixing, we ordered 500+ units to be batch produced at Batch.Works. The design for the exhibition unit consisted of 9mm OSB boxes, with birch plywood tops, held together with the Branch 3D hub and 2×2 timber uprights. The parts were all cut and assembled by final year students.

Following the show, the furniture was dismantled, packed down and reused a few weeks later for a second showing at Interior Educators at the OXO Tower Wharf Barge House.

The Branch hub is due to be used again for our next hackathon during Open House weekend at the Hithe and again during London Design Festival for a UoB exhibition showcasing work from the last 3 years of graduating students who were unable to show due to Covid restrictions.